Life

관련링크

본문

CTR’s technology has embarked on a new challenge!

Building on decades of technical expertise in the automotive industry, CTR has now taken its first step into a new frontier—the aerospace and defense sectors.

In June of this year, CTR’s Changwon Plant and CTR CHINA’s Zhangjiagang Plants (Plants 1 and 2) officially took that step by acquiring AS9100D, a specialized quality management certification for the aerospace industry.

This milestone goes beyond simply establishing a quality management system—it signifies that CTR is now qualified to participate in the global aerospace supply chain, marking a symbolic and substantial achievement.

AS9100D Certificate

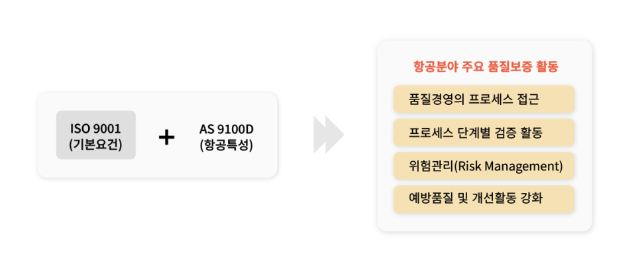

AS9100D is an international quality management system standard tailored for the aerospace, defense, and space industries.

It is based on ISO 9001 but includes enhanced requirements that address the high-risk nature of these sectors, such as product safety, reliability, anti-counterfeiting, and traceability. Because of this, AS9100D certification has become a prerequisite for supplying parts to global aerospace and defense companies.

Scope of AS9100D Certification and Key Activities for Aerospace Quality Assurance

Why did CTR pursue this certification?

CTR has recently entered into active business discussions with aerospace industry clients, making it a pivotal time to expand its business beyond the automotive parts industry into aerospace and defense. Meanwhile, the domestic defense sector is also expected to see steady growth, supported by government-led initiatives to localize weapons systems and the increase in global defense exports.

With the rise of so-called "K-Defense", Korea’s defense technologies are gaining global attention, intensifying competition among domestic and international companies to participate in major defense projects.

In light of these developments, CTR proactively pursued AS9100D certification to stay ahead of industry trends and establish a solid foundation for sustainable and stable expansion into the aerospace and defense sectors.

How Was the Certification Prepared?

The certification project was led by CTR’s Quality Planning Team, which formed a company-wide task force (TFT) to drive the initiative.

It involved extensive cross-functional collaboration between departments at both CTR Changwon and CTR CHINA, including Quality Control, Production, OE, Maintenance, R&D, Development, Production Engineering, Procurement, and Sales.

Key areas of collaboration included:

- Designing AS9100D-compliant processes and standardizing QMS documents (Joint efforts by Quality Planning, plant-level Quality/Production, OE, Production Engineering, Maintenance, and Support Headquarters)

- Training and operating internal auditors (Completion of BSI-led training and organization-wide auditor deployment)

- Localization and multilingual support for China operations (Regular online meetings with CTR Zhangjiagang’s Quality Assurance Team)

Thanks to these efforts, CTR successfully embedded the rigorous quality standards of the aerospace and defense industry into its internal systems.

CTR Changwon Plant, a key production hub where core technologies are concentrated, has reinforced its credibility with domestic clients and government agencies through this certification. It now plays an even stronger role as a leader in upholding CTR’s global quality standards.

Meanwhile, CTR CHINA Zhangjiagang Plant, one of CTR’s major global production bases, has gained a foothold in the global aerospace parts supply chain. This opens up greater opportunities for expanding business with international clients.

With this certification, CTR expects to secure new project opportunities with global aerospace and defense clients, enhance its brand credibility and technological readiness for future industries, and create synergy between its automotive and aerospace quality capabilities.

What’s next for CTR?

CTR plans to organically integrate IATF 16949 (Automotive Quality Management System) with AS9100D, evolving toward a single, unified QMS (Quality Management System).

Through this integration, CTR aims to improve the efficiency of certification maintenance and establish a solid foundation to consistently and reliably meet the quality standards demanded by global customers.

Accordingly, CTR is reorganizing its operational structure not only to advance the QMS system, but also to minimize redundant processes and documentation, while strengthening its company-wide quality culture. Furthermore, CTR plans to integrate internal audit and management review systems, enabling top management to gain a comprehensive understanding of the quality status across all sites and to make more strategic, data-driven decisions.

Moving forward, CTR is also considering expanding AS9100D certification to other facilities such as CTR Ecoforging and the Daehap Plant.

By establishing a quality management system that covers the entire aerospace component process—from forging to machining to assembly—CTR will continue to strengthen its competitiveness in the aerospace and defense industries!